Products

Specialized in general meat processing equipment!

Heat processing equipment

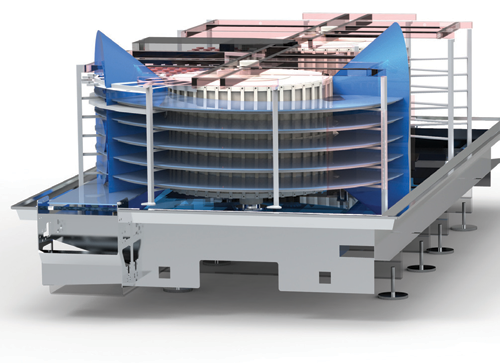

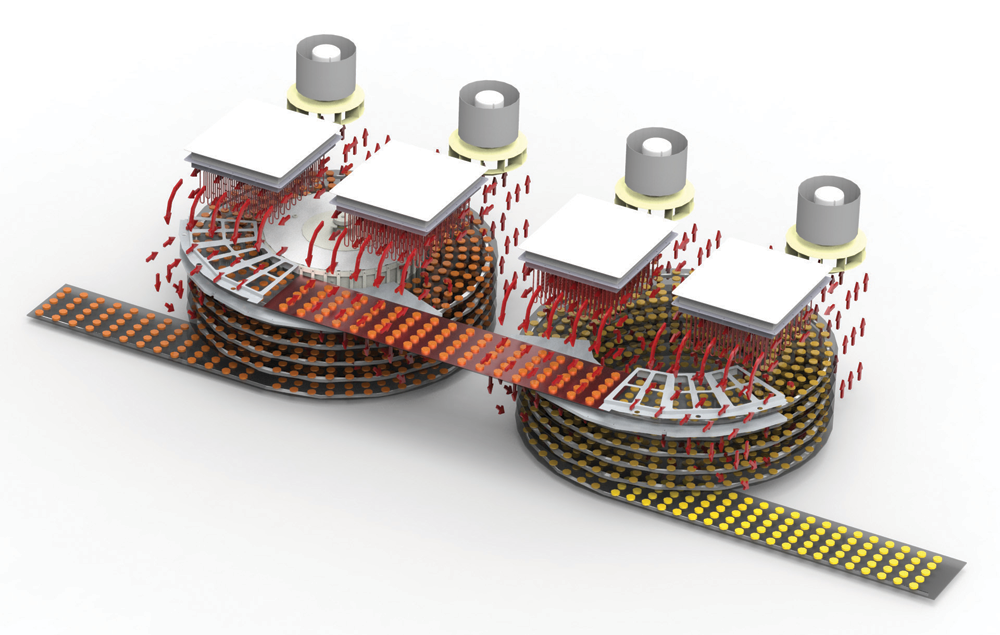

Spiral Cook and Oven

HSCO

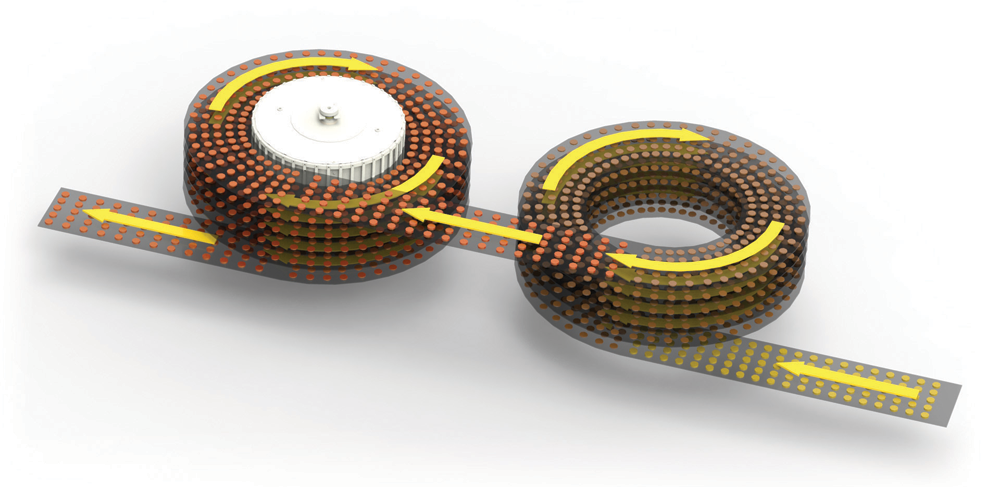

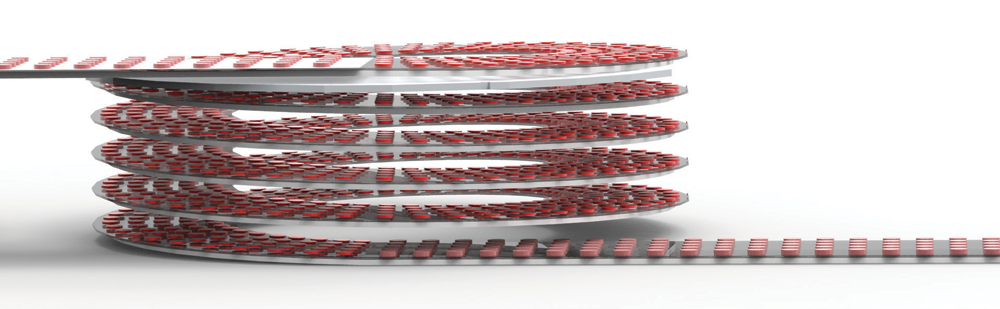

- Large capacity Spiral Cooking & Oven equipment. Spiral TWO-DRUM TYPE. Manufacturing capacity in min space is excellent.

- Steam & Oven heating in 3D Drum Up/down ensures high energy efficiency comparing to Yield per unit.

- Configuration of 2 Drums realizes various products by controlling temperature and humidity.

- The machine consists of Spiral Conveyor, Drum, heating unit, Cover Up/down System, air blasting unit, Steam Spray unit, CIP unit, tension adjusting unit.

Specification

- MODEL

- HSCO

- DIMENSION

- 4300W*9400L*4300H

- WORK CAPA

- 1~2TON/Hr

- NET

- 660W

- SPEED

- 0.7~20M/Min

- ELEC.

- 63Kw

- AIR

- 15A

- WATER

- 25A*2EA

- STEAM

- 65A

- GAS

- 50A

- REMARK

CIP System

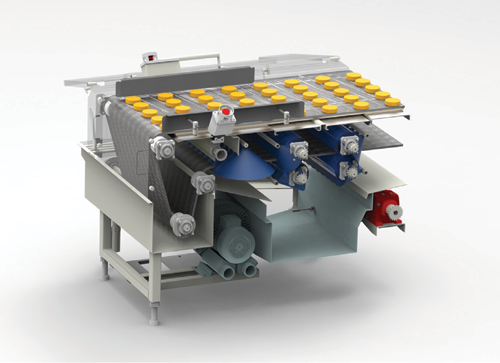

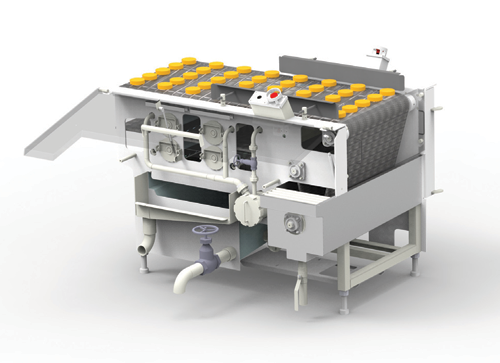

- CIP (Clean in place) System consists of unique internal and external Spray System.

- Excellent detailed washing capacity from the rotation drum to cooking zone.

- Each zone has independent CIP Tank and CIP Circulation System.

- Net cleaning can reduce 10~15% Washing time and water and detergent consumption.

- Continuous Belt Washing System enables 72-hour continuous production.

- Cleaning brush set can be easily changed for prevention of cross contamination between other products.

Applied product groups

- Oven temperature : 155℃~160℃

- Passage time : 6~8min

- Core temperature :above 80℃

- Oven temperature : 155℃~160℃

- Passage time : 25~30min

- Core temperature :above 80℃

- Oven temperature : 155℃~165℃

- Passage time : 13~15min

- Core temperature :above 80℃

Features

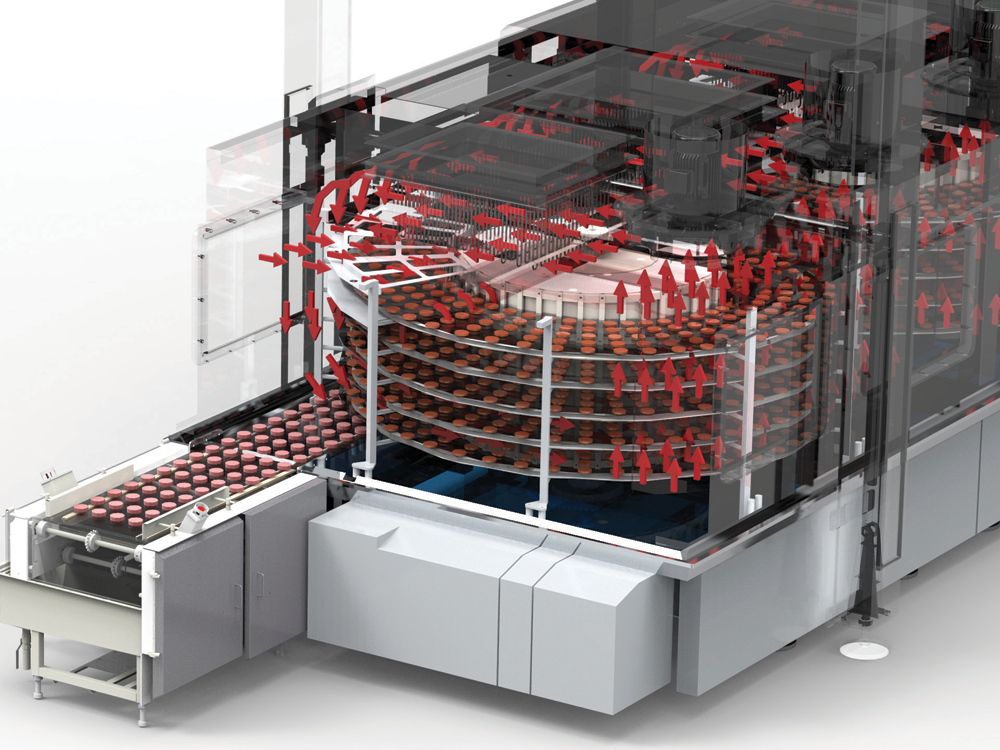

- The equipment is used for manufacturing of Steam & Oven product. It consists of Drum, Spiral Conveyor, high-temperature heating zone, CIP System.

- Adjustment of conveyor speed and internal humidity within time required to reach to product core temperature enables productivity improvement.

- Conveyor Belt is Auto Washed during operation.

- Spiral Two-Drum Type has excellent production capacity in min space.

- Steam and Oven heating in 3D Drum Up/down space enables high energy efficiency comparing to unit Yield per time.

- Two-Drum One Control using One-step Touch operation and speed, free and variable temperature operation is possible.

External Components

- Electric box, cover, humidity measuring hole, lifter, outlet, CIP, vent, control panel

Internal Components

- Spiral Conveyor, Steam Spray unit, gas burner unit, hydraulic System, air blasting unit, Belt Washing unit, Drum, spare Washing System, Conveyor tension adjusting system

Operating Principle

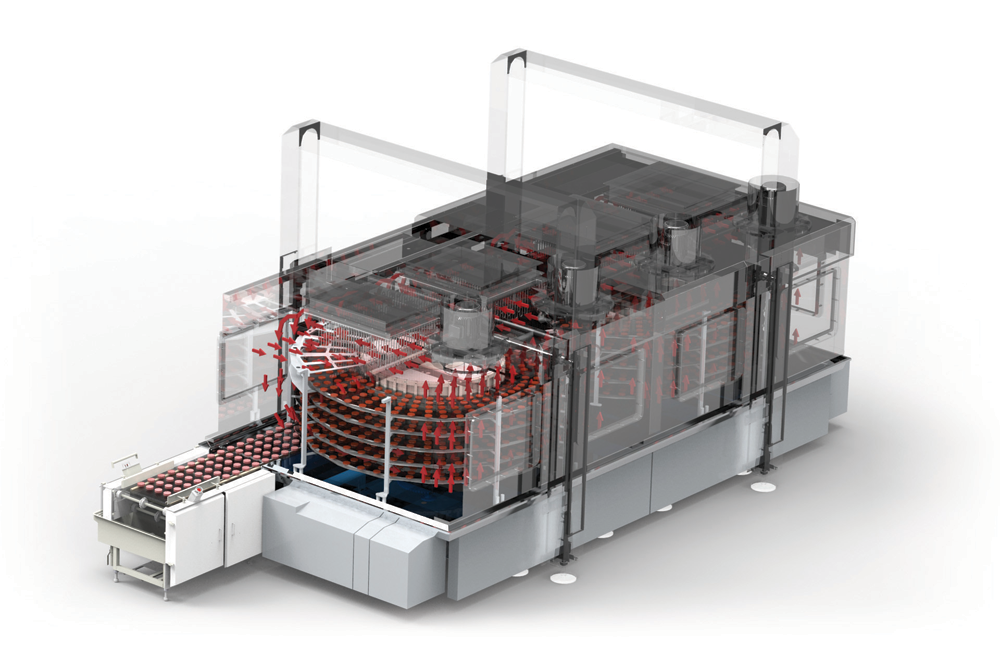

- 1st Drum Cooking space is initial heating zone. Lateral heating air flow occurs and heat is quickly transferred to product core.

- The conveyor that connects top of the 1st Drum and 2nd Drum generates longitudinal high-temperature heat (200℃~230℃) and performs browning of product surface at short time and it minimizes surface drying to help yield improvement.

- 2nd Drum secures enough core temperature and increase safety and provides more color and gloss.

- Control element: Cook Oven temperature, humidity, Belt Circulation speed and time.

Operation and thermal Circulation

- Spiral Conveyor Two-Drum Type System has excellent production capacity in min space.

- Vertical/horizontal air flow secures consistent heat transfer. Hence, consistent production is possible at certain temperature distribution for each Belt.

- Excellent heat transfer speed allows reduction of worktime (10%~30%).

- Especially, Steam and Oven are heated in 3D Drum Up/down space. Hence, energy efficiency is high comparing to Yield per unit time.

Top

Top