Products

Specialized in general meat processing equipment!

Meat preprocessing equipment

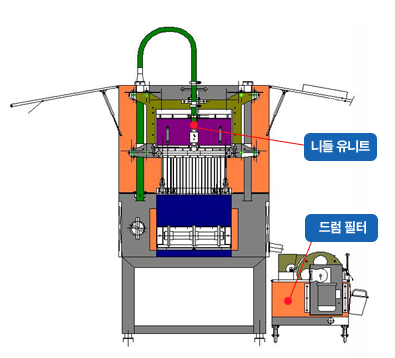

Injector

HPI-24 / HPI-70 / HPI-236

- Injector is to naturally inject chicken liquid. It provides effects of reduction of curing time effect and yield enhance.

- Basic Machine standard (Based on number of pins and Belt width)

24 PIN / 70 PIN / 140 PIN double type (200%) / 236PIN - Needle Diameter

Ø1.6, Ø2.0 for marine products, Ø3.0, Ø4.0 for meat processing - Other standards

The gap between belt width and needle quantity can be adjusted according to Customer product - Application Scope

Bacon Ham / Deliker Ham / Chicken / Salmon

- Double injection & Tenderizer

Needle

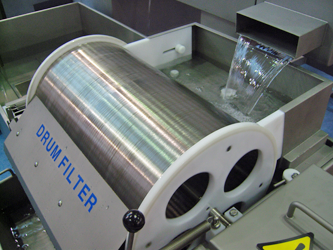

Drum Filter

Installation of double & Tenderizer

Specification

- MODEL

- HPI-24

- HPI-70

- HPI-236

- DIMENSION

- 730W*1150L*2100H

- 2000W*2500L*2600H

- 2000W*2700L*2600H

- BELT WIDTH

- 254W

- 430W

- 580W

- WORK CAPA

- 150~180 chickens/Hr (Based on chicken)

- 2500~2800 chickens/Hr (Based on chicken)

- 3200~4000 chickens/Hr (Based on chicken)

- ELEC.

- 3Kw

- 4.5Kw

- 10Kw

- AIR

- 15A

- 15A

- 15A

- REMARK

Machine Configuration based on 236pin

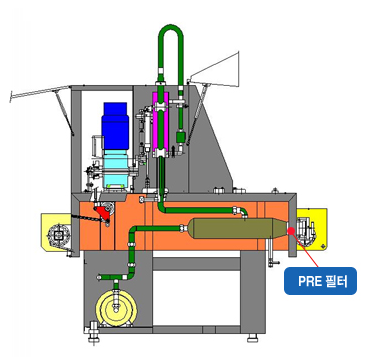

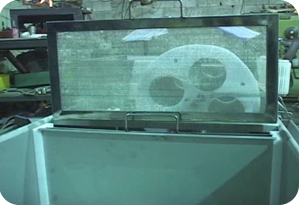

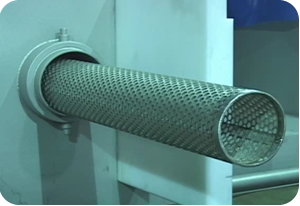

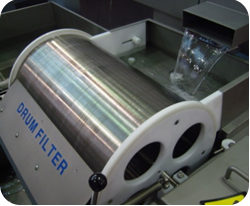

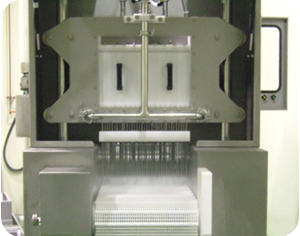

01Triple Filter System

- FIRST : Cassette type

- SECOND : Round mesh Filter

- THIRD : Drum Filter

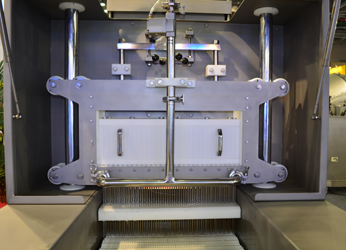

02One-touch Handle operation to separate Needle Block

Assembly/operation ready status

One-touch Disassembly Handle

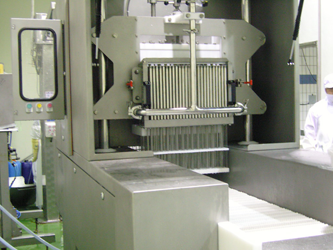

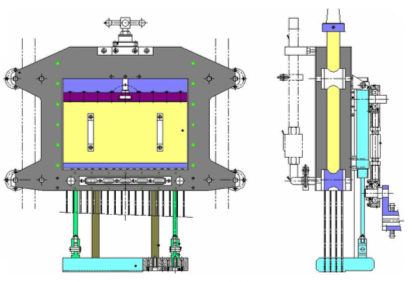

03Meat (material) overflow prevention

It prevent meat (material) from moving up along with the needle during injection and naturally press meat to prevent pickle liquid from running over from meat during injection

Top

Top