Products

Specialized in general meat processing equipment!

Meat preprocessing equipment

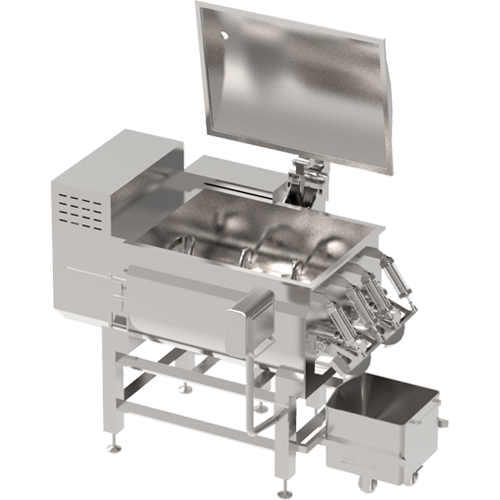

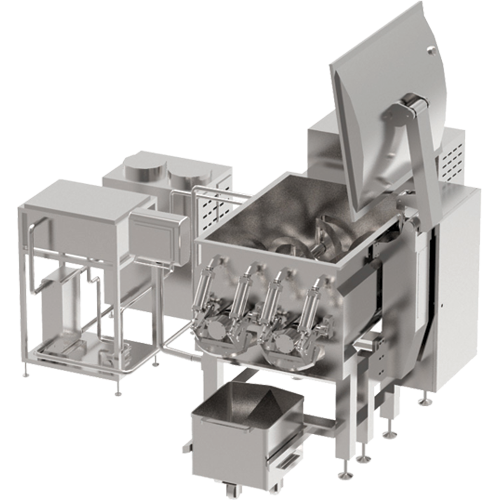

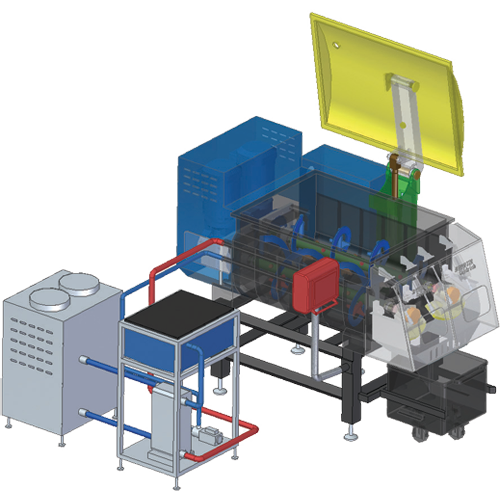

Chiller Mixer

HVCM-1200

- Meat mixing equipment. Meat temperature rise due to frictional heat generated in the mixing process is shut off for easy elution of enough salt-soluble and it helps product property and texture to increase after Heat Processing.

- In addition, meat and additives are mixed in Vacuum State to suppress bubble generation and to reduce mixing time.

- A double jacket is configured to control temperature inside the tank. Food glycol is used as refrigerant. Maintain meat temperature lower than 5℃.

Configuration

- DUAL JACKET TANK

- WAGON LIFT

- IMPELLER

- VACUUM PUMP

- Freezer

Specification

- MODEL

- HVCM

- DIMENSION

- 3200W*3500L*2800H(3400H)

- HOPPER

- 1200L

- WORK CAPA

- 800L

- RPM

- 37RPM

- ELEC.

- 48Kw

- AIR

- 15A

- Freezer

- 25HP

- REMARK

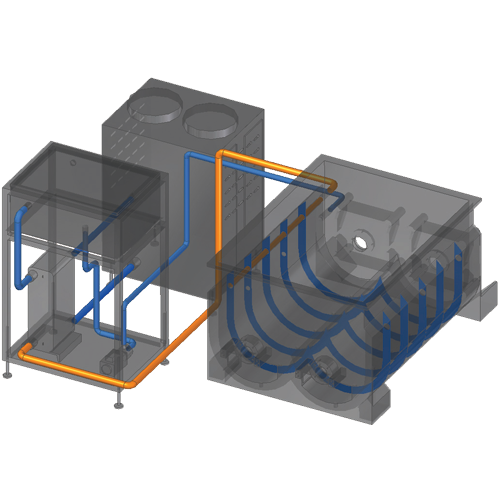

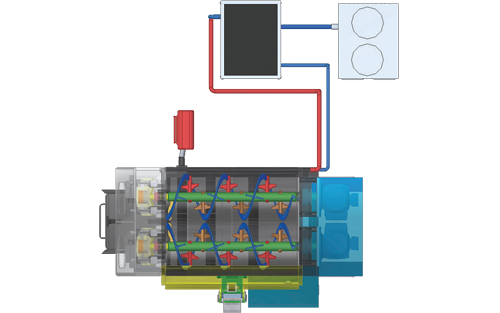

01 Chiller Water Circulation

-20℃ of glycol fluid is circulated through the tank jacket and the internal Impeller repeats forward run, backlashing and pause to certainly maintain low temperature of Mixed Meat.

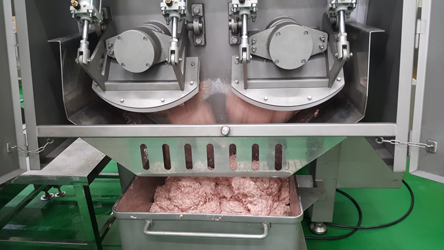

02 Double IMPELLER

A paddle type Impeller is additionally installed on 2 main screw axes for more effective mixing.

Top

Top