Products

Specialized in general meat processing equipment!

Sterilization Machine

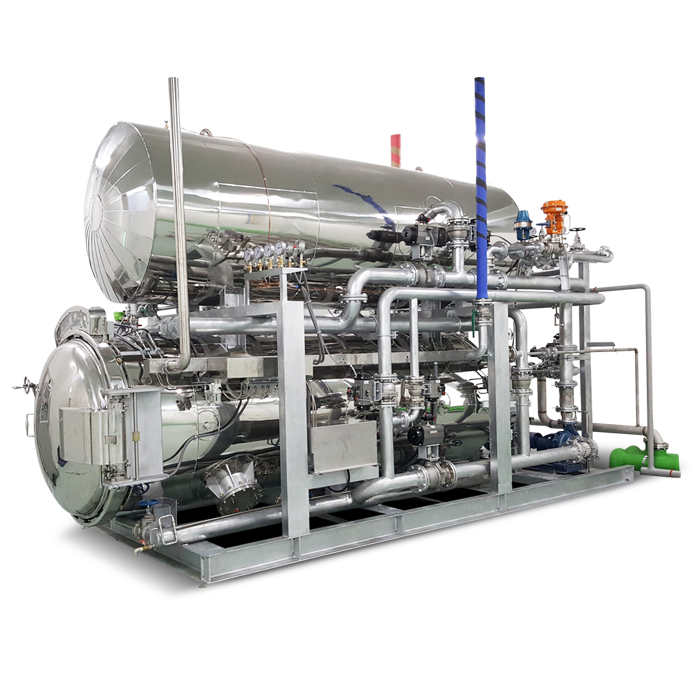

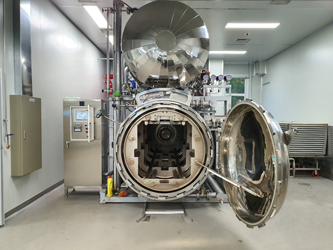

Retort

HSR / HWR /HRR

- Retort product refers to giving aseptic inside and outside the product with high temperature, meaning a food product that has been loaded with cooked processing food in film container composed of pouch, aluminum, bottle, can, etc., vacuum sealed, pressured, heated, sanitized and cooled. Initial method involved a steam type method that consumed too much energy and which couldn’t maintain consistent temperature difference within the tank but moved onto use the hot water (inundation) method to enhance product quality. Currently we use shower, spray method which greatly reduces hot water type’s shortcomings and energy consumption amount while increasing quality.

This method has lowest amount of energy consumption and temperature difference not to spoil taste and color due to short staying time at hot temperature.

Pasteurization (70-80℃) process can be used and temperature can rise for each time and step.

Pasteurization (70-80℃) process can be used and temperature can rise for each time and step.

Water cascading & inundation & rotation

The method heats up water in the upper tank and drops. It is most widely used.

Specification

- MODEL

- HSR

- DIMENSION

- 2750W*4800L*2700H

- 3100W*4900L*2700H

- TANK

- Ø1250

- Ø1370

- CART

- 4

- 4

- ELEC.

- 21Kw

- 23Kw

- AIR

- 40A

- 40A

- WATER

- 65A

- 65A

- STEAM

- 65A

- 65A

- REMARK

- MODEL

- HWR

- DIMENSION

- 2600W*6200L*3600H

- 2600W*6200L*3700H

- TANK

- Ø1250

- Ø1370

- CART

- 4

- 4

- ELEC.

- 40Kw

- 42Kw

- AIR

- 25A

- 25A

- WATER

- 125A

- 125A

- STEAM

- 65A

- 65A

- REMARK

- MODEL

- HRR

- DIMENSION

- 2600W*6200L*3700H

- TANK

- Ø1370

- CART

- 4

- ELEC.

- 45Kw

- AIR

- 25A

- WATER

- 125A

- STEAM

- 65A

- REMARK

Top

Top